Automation Engineering

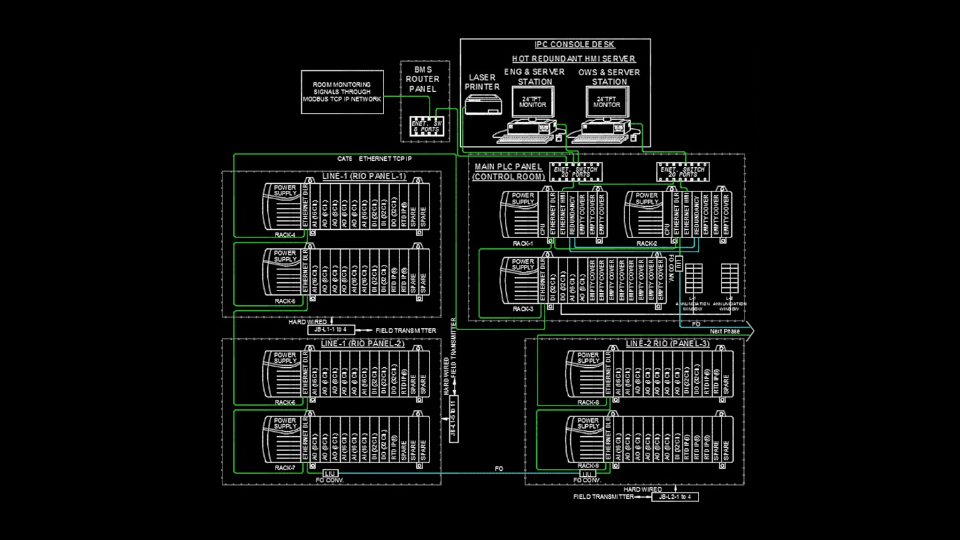

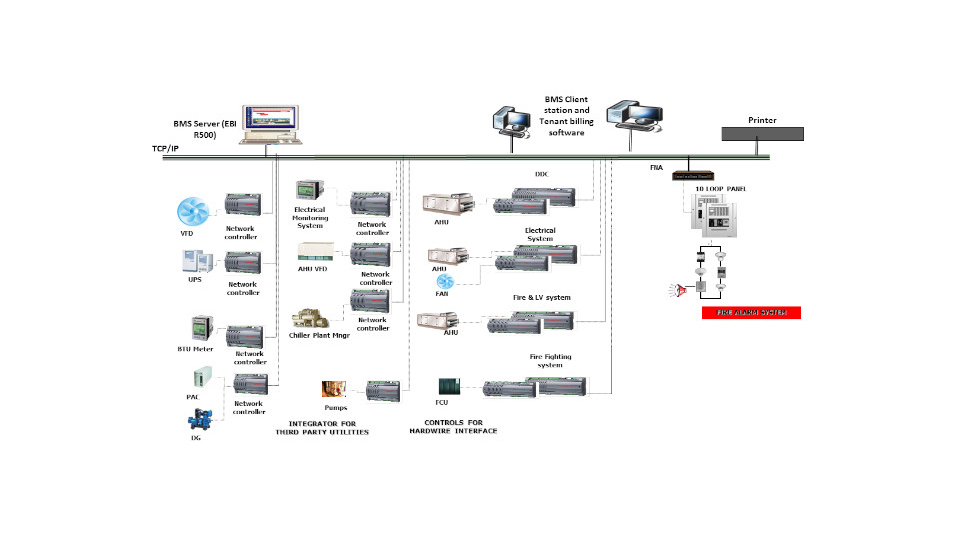

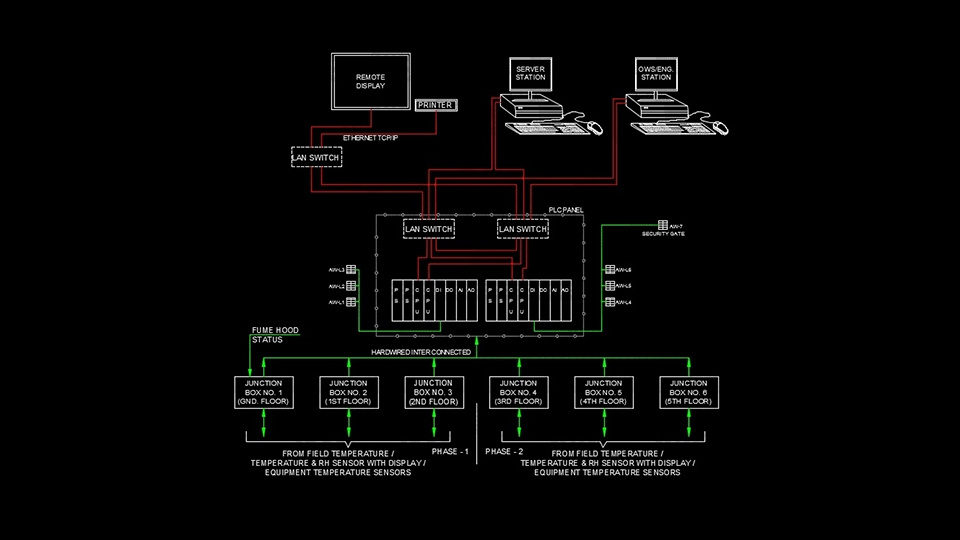

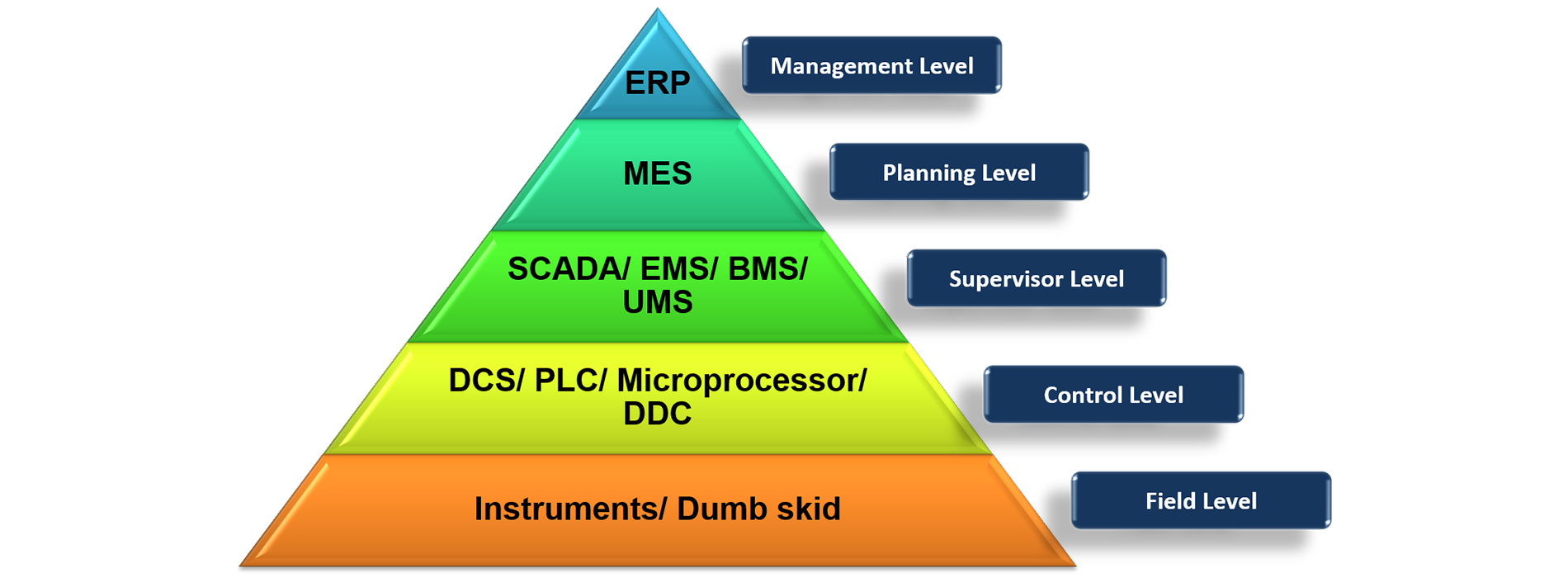

Elomatic offers comprehensive know how of automation architecture with various combination permutations based on clients business plan and application complexity. Elomatic has successfully executed multiple projects with various level of automation. Such automation design & execution involves PLC, SCADA, DCS systems.

Design is customized based on customer applications inclusive of data management and reporting system which are of high quality, error free, flexible, cost effective & customized. We have multiple successfully design – build manufacturing facility under full compliance of GAMP 5 & CFR 21 part 11 guidelines.

A process automation is used to automatically control, monitor & report the various process activities Robotic process and intelligent automation tools can help life science and healthcare industry to improve the effectiveness of services faster and at a lower cost to mankind. LIMS is a software – based solution with features that support a modern laboratory’s operations with data exchange interfaces. LIMS allows you to manage samples, test results and associated data to improve lab productivity. The audit and revision control functions in a LIMS are key reasons why people use a LIMS and ‘Go Paperless’. Similarly, the automation can be offer for Utility Management System (UMS).

With the rapid development of the industry, high – speed, high – efficiency and accurate delivery have become the new pursuit goals of the intelligent logistics & automation in warehouse has been highly favoured by life science and healthcare industry. In the automated warehouse, Warehouse Management System (WMS) plays a vital role. As a bridge connecting software and hardware, the WMS realizes the automated storage of off – line products and meets the needs of industry for unmanned warehouses and high efficiency. The pursuit of data management has brought competitiveness and vitality to the industry and has created enormous economic value. Warehouse management system reduces the overall cost of inventory management.

Autonomous Guided Vehicles (AGV) are used to optimize the warehouse operations and to validate the inventory quality assurance. Automated Storage and Retrieval Systems (AS/ RS) systems are one of the most complex part of warehouse automation, and enable the automated storage of crates and pallets after delivery from supplier and the retrieval for the order picking process. It also includes automated racking, shelving, and shuttle systems and allows for far denser warehouses. The warehouse automation is totally customised based on applications and client’s needs.

We offer the end to end solutions for plant automation inclusive of process automation, BMS, EMS, WMS, LIMS, e-BMR and FMS hook – up with ERP system.