Decontamination Design

Biosafety regulation aims at protecting human health and environment from biohazards, all biohazardous waste generated in biocontainment facilities must be decontaminated prior to discharge. In case of high bio – containment, the decontamination may also be required like in BSL4 facilities or even in BSL2 (Optional)/ BSL3 for potentially biologically contaminated effluents depending on the used biological agent.

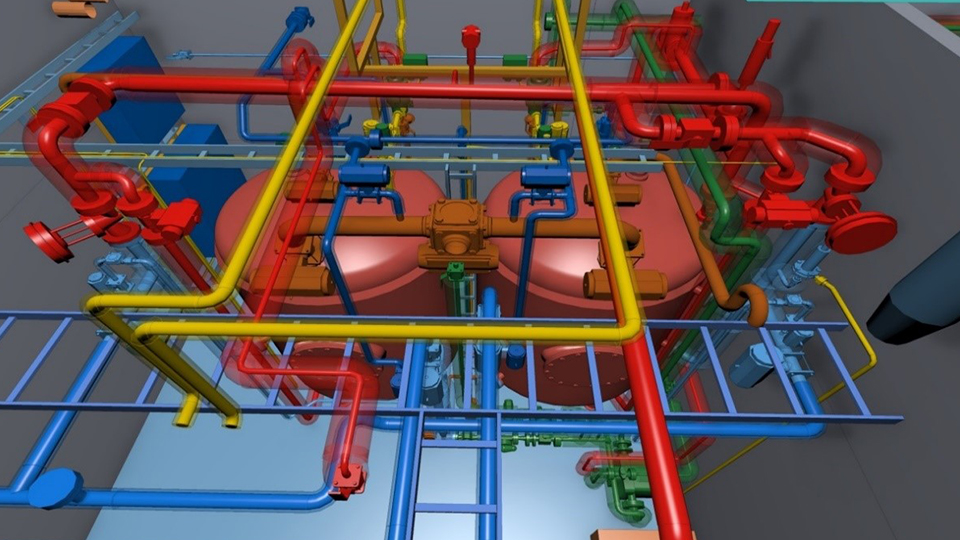

Biokill system is the effectively sterilization used to destroy all microorganisms including large numbers of bacterial spores. Heat treatment is most effective for sterilizing wastewater that contains high levels of solids. These systems usually have tanks where wastewater is treated at high temperatures and pressures.

Autoclaves may be used for treating small quantities of liquid wastes in laboratories. Large animal facilities and those with high numbers of small animals may require large centralized wastewater treatment systems.

Chemical treatment systems can be used successfully in some applications, although they are not as effective in treating wastewater from animal facilities because of potential interference with chemical disinfection by solids in the wastewater.

While doing the design & engineering of the Biokill system, there are multiple factors to be consider like type of micro – organism species, biohazard level classification of pathogens (CDC-NIH), biohazard risk, containment level, Good mixing of chemical additives for defined period, uniform sterilization temperature for defined period etc. Additionally the overall safety factor in the operation of biokill system need to be taken care while doing the design. The biokill system is fully supported with qualification documentations and is validated system.