Process Engineering

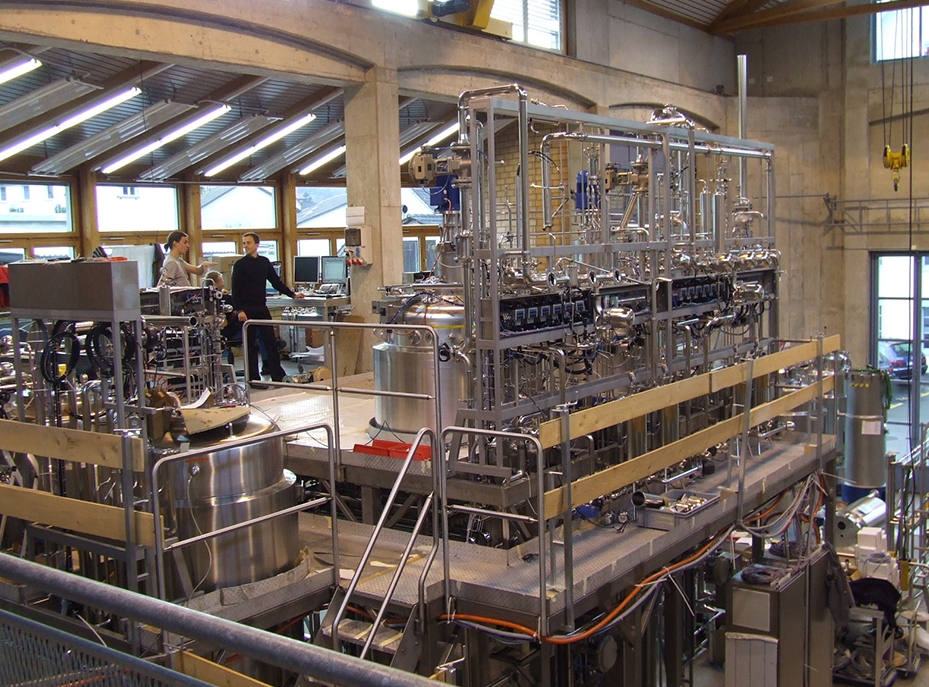

Our mission is to make you experience our Process Engineering expertise in Life Science industry. Process Engineering typically involved the understanding of the process followed by written down process description, process flow diagram (PFDs), functional specifications, mapping & selection of suitable technologies, unit operations, P&ID, Integrated P&IDs, process simulation (on special request), energy balance, mass balances, material flow, process equipment sizing, production line balancing, selection of components/ equipment, preparation of URS, technical sheets (TS) and data sheets (DS) of process equipment, process interconnecting piping, CIP & SIP strategies and design, risk analysis, ATEX classifications, isometric drawings, process automation etc. This entire gamut of process engineering is done under strict compliance of GMP and regulatory guidelines.

The proof of our know – how and experience in life science industry are the numerous facilities we have designed which have passed inspections by the WHO, Schedule M, EMEA, PICs, USFDA, TGA, UK MHRA etc. We comply with good engineering practises (GEP). Our goal is to create added value for our customers: time and cost savings in Design, Commissioning, Qualification and Validation.

At Elomatic, ASME – BPE is inbuilt part of Process Engineering. As you know that ASME – BPE is the leading standard on how to design and build equipment/ systems used in the production of biopharmaceuticals and sterile applications. This ensures the current best-practices for enhancing product purity and safety.

In biotech/ vaccines/ biopharmaceuticals our process expertise covers all process phases from upstream processing to downstream purification with a variety of strategies for buffer, media, purification processes etc. We also have multiple experience of Bio-Safety Level 1 / 2 / 3 / 4 (BSL1/ BSL2/ BSL3/ BSL4) facilities.

Our core strengthen is our deep understanding of technical requirement of the various processes & their application areas.

We have proven experience in :

- Oral solid dosages (Tablet & Capsules)

- Liquid syrup

- Dry Syrup/ suspensions / Sachets

- Ointments/ creams

- Large Volume Parenterals

- Small Volume Parenterals

- Complex injections

- Eye/ Nasal drops

- MDI/ DPI

- Sterile API

- No Sterile API

- Highly Potent API

- Chemicals/ Speciality chemicals

- Oncology formulations

- Hormones/ Steroids Formulations

- Containment facility

- Medical Devices

- Pilot facility

- R&D Labs

- Biotech manufacturing processes

- Biopharmaceuticals

- Gene Therapy

- Human Vaccines

- Animal Vaccines

- BSL 3/ BSL 4 Facilities

- Plasma Fractionation

- Diagnostics Kits production

- Cosmetics

- Veterinary formulations

- Enzymes